- Get link

- X

- Other Apps

- Get link

- X

- Other Apps

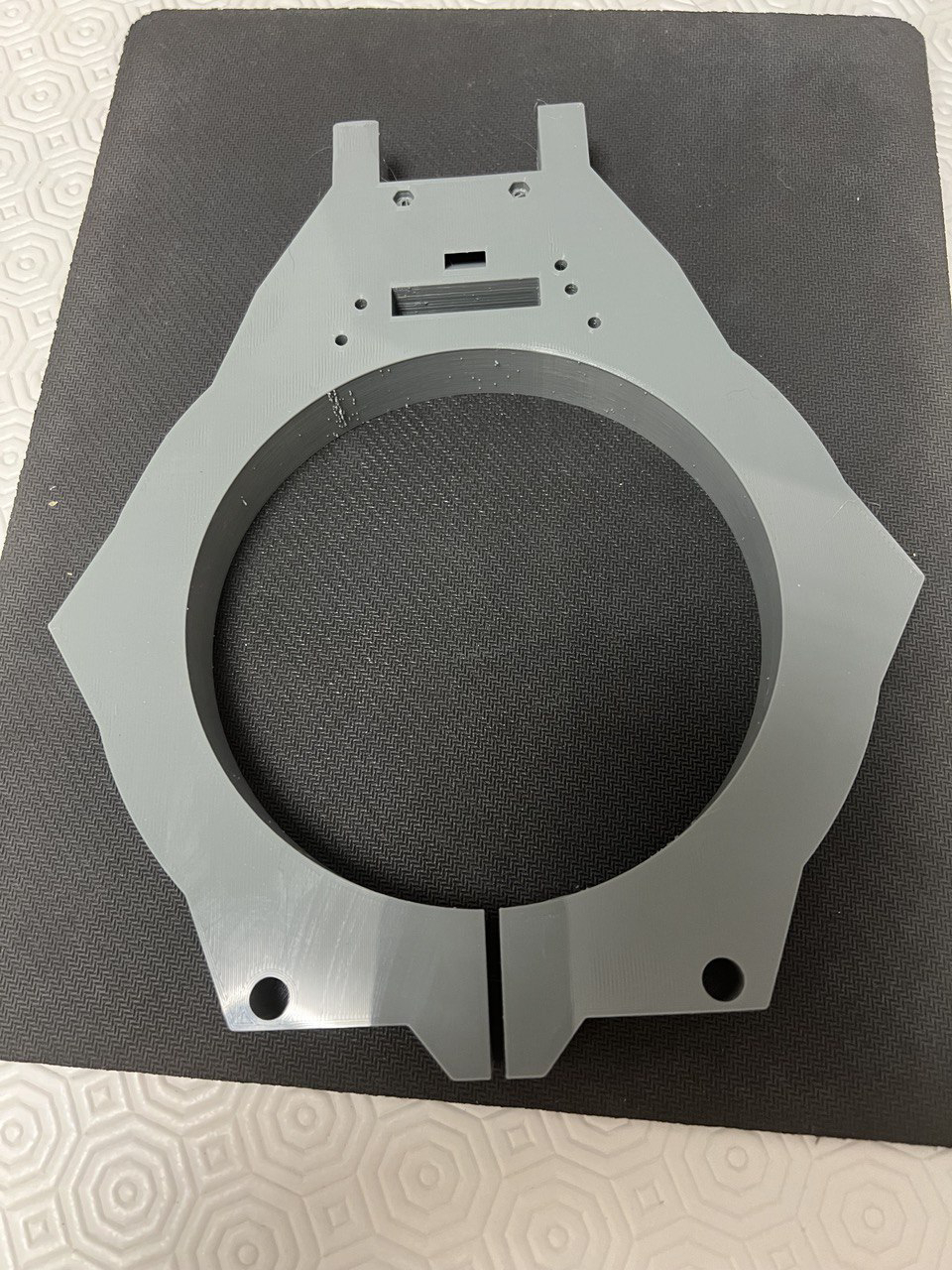

Building a Nuno's Robotized Flat Field Cover for Astrophotography

Astrophotography is a fascinating practice that allows for the capture of detailed images of the cosmos. However, it requires specialized equipment to ensure the stability and precision needed for long exposures. In this project, we developed a Robotized Flat Field Cover specifically designed to perform flats, which are images used to calibrate astronomical photographs, removing imperfections and enhancing the final photo quality.

Project Objective

Create a Robotized Flat Field Cover capable of performing flats efficiently and precisely, and protect the lenses from dust and atmospheric conditions. All that using readily available market materials and 3D-printed components. The project aimed for high precision and durability, ensuring ease of assembly and maintenance.

Materials Used

Microcontroller (such as Arduino)

Servo motors

Led Strip

Power supply

3D Printing

PLA(tests) PTEG filament

Screws and nuts

Some programming language's

Build a ASCOM driver

Project Development

The first step was to plan the structure and necessary components.

We used 3D modeling software to design the parts to be printed.

The design included:

A stable base to avoid any vibrations.

Adjustable supports.

Space to accommodate all electronics.

3D Printing

With the design finalized, we proceeded to print the parts. Filament selection was crucial to ensure strength and durability. We used PTEG filament for most parts due to its ease of use and suitable properties for our application.

Mechanical Assembly

The structure was 3D-printed parts. Screws and nuts were used for firmness.

Electronic Integration

The electronic components were integrated based on the following scheme:

The microcontroller was programmed to control the servo motors and the light.

The light were strategically positioned to automatically adjust the exposure of the photos.

Programming and Testing

We developed specific software to control the robotized structure. This software allowed:

Precise movement of the motors.

Automatic adjustment of light exposure for each flat.

User-friendly interface to configure and start the flat capture process.

Tests were conducted in various conditions to ensure the system's precision and effectiveness. Fine adjustments were necessary to optimize performance.

Refinement and Optimization

After several iterations and adjustments, the structure reached the desired level of perfection. Issues such as unwanted vibrations and movement inaccuracies were eliminated.

Results

The project resulted in a robust and efficient structure capable of performing high-quality flats for astrophotography. The integration of 3D-printed components with market-available materials proved to be an effective and economical solution.

Conclusion

Developing a robotized structure for astrophotography was a rewarding challenge. The use of 3D printing allowed for the creation of customized and precise parts, while the combination of electronic and mechanical components ensured the system's functionality and precision. This project not only improved the quality of astronomical photos but also demonstrated that people are awesome in the potential high-tech projects.

The project Robotized Flat Field Cover was designed and built by Nuno's.